Description

• Allows to manufacture up to 1,500 litres per turn ice cream .

• Continuous operation is remarkably easy to operate.

• Incorporation of air (overrun) up to 100%.

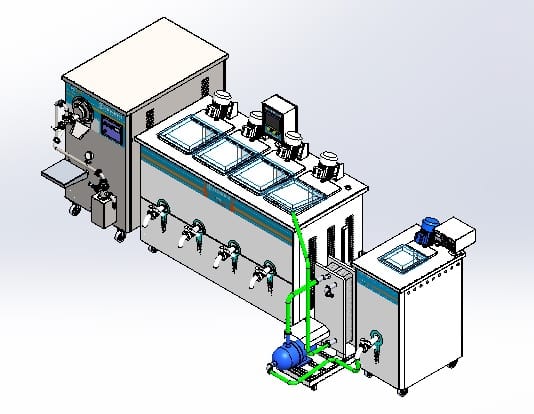

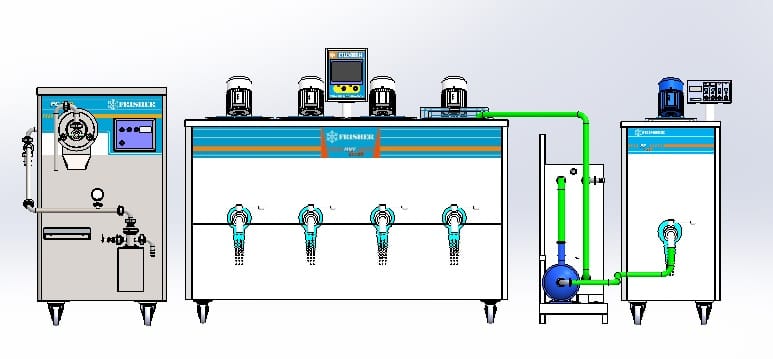

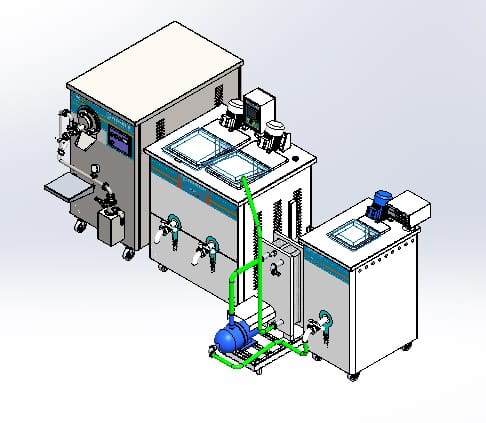

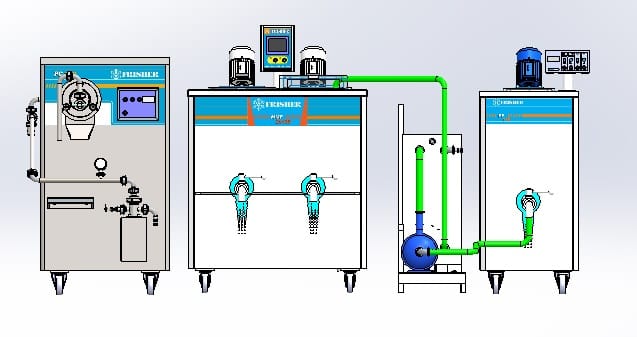

• Compact plant that can be installed on a surface area less than 5 m2 (6 m2).

• Easy to clean.

• Pumps, valves and download fulfilling the most stringent sanitary standards.

• Making Continuous PC 200 with the following features:

– Electronic Control of the speed of production .

– New control of the consistency of the ice cream.

– Light-signalling of the protections.

• Pasteurizer PF 110 that enables you to handle loads of up to 100 litres of mixture every 40 to 45 minutes, obtaining during this operation a substantial reduction in the size of the fat particles thanks to a product-mixer of high efficiency.

• Tub of Maturation MMF, can be combined into 2-or 4 bocas

features:

– Cool built-in high thermal efficiency

– control by touch panel, which allows you to program and control the temperature, timing of the stirrer, and a unique system of autodiagnico and alarms that guide the operator to solve the problems